The NuStory Rug Journey: From Inspiration to Last Loop

Handcraft is our heritage and future. From ideation to production, each part of our process is guided by human hands, and we’re focused on ensuring our skilled weavers work in an inspiring, supportive, safe environment.

Our workshop in India carries the SA 8000 Standard, the leading international social certification for factories.

Here, we share the many steps that go into creating uniquely designed, sustainably made rugs for our customers.

1. Source of Inspiration

Every rug has a story and setting: the time and place that inspire its design. Based in NYC, our designers craft narratives for each collection — carefully curating rugs to fit trends, inviting color schemes, and refreshing themes. From Upstate to Highrise, each collection tells a different story through distinct yet versatile styles.

2. Design Exploration

NuStory designers are textile experts. With an intimate understanding of weaving materials and a profound knowledge of contemporary art and design, they merge traditional craft with innovative technology. This fusion pushes the boundaries of color, texture and pattern, resulting in original designs and material masterpieces.

3. Color Customization

Our expert team formulates colors from an array of pigments. Each hue can be customized in 100 shades, and our in-house, ongoing research continually expands this palette. By customizing colors, we perfectly match the design while creating a distinct palette.

4. Rigorous Sampling and Testing

We place immense emphasis on achieving impeccable quality. Rigorous testing occurs at every stage, from assessing raw materials to matching and standardizing colors.

5. Precise Dyeing

Different fibers demand distinct dyeing methods. We employ over 1,000 machines to execute lower-impact dyeing procedures, upholding our high sustainability standards. For example, these machines help us conserve and treat residual water, reducing consumption by up to 90%.

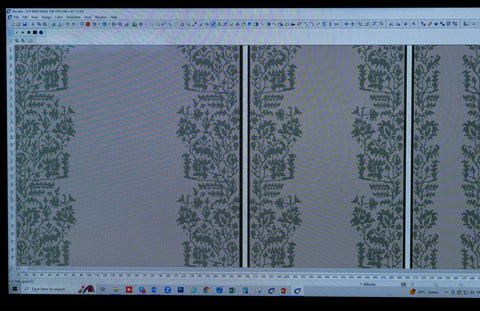

6. Mapping the Masterplan

The naksha (Hindi for map) serves as the blueprint for a carpet. While a naksha is traditionally hand-painted, we now use modern technology — such as state-of-the-art CAD systems — to render these masterplans.

7. Preparing the Loom

Weavers meticulously prepare the loom with the predetermined number of warps for weaving. Supervisors ensure the correct naksha, yarn tufts and materials are assigned to each weaver, who systematically arranges the wefts before the commencement of daily work.

8. Weaving

Weaving is a highly skilled process. Some weavers tie up to 9,000 knots in a day, and some carpets may take up to a year to complete. Weavers are experts at using specialized tools, like the chura — a precision metal blade that can cut knots evenly without damaging the yarn.

9. Washing

The washing processes define the carpet's final look and feel. Washing eliminates foreign particles and imparts a soft luster to the carpet. At this stage, we also use exclusive finishes to prevent shrinkage and shedding.

10. Off-Looming and Inspection

Having undergone our sustainable dyeing, weaving and washing process, the fibers are carefully removed from the loom. Inspection occurs during weaving, and after the carpet is taken off the loom. Precise oversight results in a perfect balance of art and craft.

12. Final Designer Approval

The ultimate seal of approval comes from the designer, who ensures that each rug meets their high standards. Now the rug’s story will continue with the customer, who brings home the work of every artisan along the way.

The Last Loop

From early sketches to the final nod of approval, our process represents our dedication to artistry, quality and innovation. We’re grateful that NuStory’s direct line to customers allows every person who buys our rugs to continue the story in their space.

To learn more about our people and process, visit here.